Fighter jets often have fuel stored behind the pilot’s seat, but big airliners like the B747 store massive amounts of fuel in their wings. So what is the benefit of having fuel stored in the wings of an aircraft? And does it pose any risks to safety?

Table of Contents

Why is Fuel Stored in the Wings?

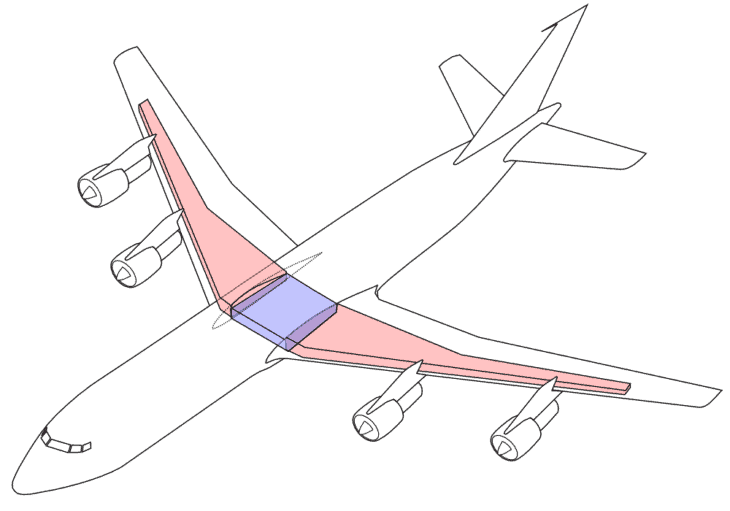

There are several reasons fuel is stored in the wings but the main three reasons are to balance weight, counter-stress and reduce wing flutter.

Benefits of Wet Wings

There are many ways to store fuel in an aircraft but by far the most common method today is via integral tanks within the wings aka ‘wet wings’. This method uses the aircraft wing structure, completely sealed, as a fuel tank instead of fitting a dedicated container inside the wing.

Efficient use of space

The electrical and hydraulic components used to control the ailerons and flaps inside the wing only occupy a small percentage of the space available so using the wing itself to store fuel is a very efficient use of space, as it is too narrow to be used to store any significant amount of cargo.

Cost savings

With no need for a tank, wet wings generate considerable cost savings for the manufacturer. Heavy tanks and bladders need regular maintenance and limits the amount of payload (passengers or cargo) the aircraft can carry. With less maintenance and more payload, this design was putting dollar signs in the eyes of potential buyers.

Although integral fuel storage has been done for many years, it was not normally used to carry the bulk of the fuel. Whilst some photo reconnaissance versions of the spitfire had fuel stored within the leading edge of the wing and drop tanks the primary fuel source was still within the fuselage.

It wasn’t until the 1950s however that wet wings became widely used. With the development of faster and more flashy aircraft, wings were made to be more rigid to withstand the higher performance.

Gravity feed

These stiffer wing structures were much more appropriate for fuel storage. As you might expect the left engine is supplied by the fuel in the left wing and vice versa. One benefit of storing fuel in the wings is the ability to gravity feed.

Should the fuel pumps break or a fault occur, the engines will still be fed with gravity. Additionally, today’s aircraft usually have ‘centre tanks’ in their bellies. As this reserve sits below the engines, gravity feeding from this area is not possible. This fuel is therefore depleted first to ensure gravity feeding is always available as long as there is fuel onboard.

Weight Balance and CofG

The wings are located close to the aircraft’s centre of gravity (CofG). If the aircraft is loaded too heavily to the front or rear of this point the aircraft will suffer from performance issues or even tip over on the tarmac.

Storing the fuel at the centre of the aircraft means the CofG will remain more or less constant throughout the flight, no matter how long its duration. If the fuel was stored at the nose or tail of the aircraft, the shift in momentum would be much larger. Such a deviation from the CofG is undesirable as it affects stability and controllability.

Fuel Leaks

The difficulty of wet wings however is that the wing itself must be water-tight. Developing sealants able to withstand the violent atmospheric changes involved in flying was a challenging journey and so many early aircraft with this fuel storage solution struggled to avoid fuel leaks.

The DC6 was notorious for fuel leak which caused several fires and even the famous Lockheed SR-71 Black Bird struggled to solve this problem. The plane was famously known for leaving fuel on the tarmac before it took off, and was refueled almost immediately after takeoff.

The aircraft could fly in temperatures below -60℃, but flying at more than 3 times the speed of sound caused its skin to heat up to over 300℃. That’s a huge temperature range for any material to withstand and so trying to find a sealant capable of maintaining its integrity throughout was impossible.

The solution to this particular problem came from a simple bit of physics: the laws of thermal expansion. As the aircraft reached high speeds the skin would heat up and expand, closing the gaps and stopping the leaks.

Airlines today do not of course fly supersonic, so there is no need to allow for the effects of thermal expansion.

Preventing Sloshing

One risk associated with wet wings is the sloshing of fuel during flight. Cargo is placed and secured meticulously to prevent the loads shifting during flight and potentially causing catastrophic accidents. So how is the movement of fuel contained?

The fuel tank of a car is a simple box allowing fuel to slosh around freely. The greatest implications would be struggling to climb a steep hill if you’re low on gas, but as with everything aviation related, the implications of sloshing within an aircraft are much more dramatic.

An Airbus A380 can carry upto 82,000 gallons of fuel which weighs around 293,000kg. Imagine that dancing around the aircraft’s wings during turbulence or whilst carrying out a manoeuvre. It would not be a pleasant experience.

Baffles are used to help control the movement of the fuel. These are large pieces of metal with a hole through the middle, allowing fluid to pass through. Placed side by side across the span of the fuel cell, they are a simple, yet effective solution.

Take a look at this video to see how baffles help to control fuel sloshing.

Mitigating Aeroelastic Flutter

Flutter might sound charming when associated with butterflies, but when discussing aircraft the concept is much more alarming.

It is defined as an ‘unstable, self-excited structural oscillation’ caused by airflow over the wings. In other words, it is when atmospheric conditions make the aircraft surfaces vibrate so much that they will eventually break. Preventing this is one of the most important reasons that fuel is stored in the wings.

But flutter is not just associated with aircraft. In 1940 the Tacoma Narrows Bridge in Washington became subject to flutter during high winds and totally collapsed. This video (with a rollercoaster of a soundtrack) shows what happened to the bridge and exactly why flutter is so deadly.

The aircraft structure will ‘damp’ oscillations upto a certain speed, absorbing the energy increase and preventing the amplitude from growing. But accelerate beyond this speed and the vibrations will grow in size until the structure fails.

Filling the aircraft wing with fuel helps to mitigate such catastrophes. By increasing the rigidity of the wing structure, the flex of the surfaces is limited, allowing the aircraft to reach a higher speed before flutter occurs.

Flutter was not properly understood for many years and a catalogue of mysterious accidents have now been retrospectively attributed to it. Today thankfully engineers and test pilots are aware of this phenomena and conduct tests to discover the highest speed at which the wing’s structure will damp flutter.

This speed is usually around the design dive speed which is at least 1.4 times the cruise speed and well above the ‘never exceed’ speed. So as a passenger you can rest assured that you will be travelling well below this threshold.

Wing Stress Reduction

Although I’ve mentioned the benefits of a stiff wing above, it is still important for the structure to be able to flex a little, as it significantly improves lift characteristics and flight stability.

If all of the aircraft’s weight, including the fuel, lies in the fuselage when airborne the wing root carries the brunt of the load. This causes considerable stress to the airframe over time and reduces the time until it requires replacing, otherwise known as its fatigue life.

By storing fuel in the wing, the increased rigidity makes it more difficult for the wings to bend upwards, and with less stress on the wing root more weight is able to be carried and less maintenance is required.

Fuel Imbalance

One threat that comes with feeding fuel from the wings is fuel imbalance. If we use too much fuel on one side are we doomed to fly at a jaunty angle for the remainder of the flight?

This can occur for a variety of reasons. The APU (auxiliary power unit) is often fed from the left fuel tank, so extended use on the ground will often lead to an imbalance.

Other causes could be acceptable variations in the age and/or performance of various fuel components. More serious causes might include structural damage.

If spotted in time, a fuel imbalance is nothing to be alarmed about and can be easily rectified by the crew. To rebalance the tanks manually, only fuel from the heavier side is used until the balance is restored.

Large and dramatic imbalances however are cause for concern and can be the sign of a fuel leak. Most crews will conduct regular fuel consumption checks throughout the flight to actively monitor this.

Fire

It is no secret that fuel is extremely flammable, and with many electrical and heat-producing components onboard, placing fuel in the wings has the added benefit of keeping these fire risks further away from passengers in the event of ignition or explosion.

Time

When it comes to handling aircraft fires, time is money and pilots are urged to get the aircraft on the ground ASAP to increase the chance of survival. As many firefighters will iterate, flames are only part of the threats associated with fuel-fed fires.

Fire safety legislation is built around survival time. This is measured in post-crash survivability, ie the time available for passenger evacuation. Fuel tank materials must be able to withstand flames for 5 minutes without burning through. This is approximate the same time it takes to boil an egg.

This may seem like a scarily small window to escape, but crews are trained to evacuate all passengers within 90 seconds. A full A380 even managed to do this in 78 seconds. So 5 minutes would be sufficient to evacuate 3 times over.

Separation

Toxic fumes and thick black smoke are often the cause of fire related fatalities, obscuring the pilots’ view and asphyxiating those onboard before they are able to land. Fires and fumes in the wings are easier to isolate and with the source outside of the fuselage, there is less chance of smoke entering the cockpit or the cabin.

Most wings are made of extremely fire-resistant aluminium. The material can withstand fire for 5 minutes and it dissipates heat, preventing hotspots from occurring and minimising the risk of explosions. Additionally it allows the wing to maintain its load-bearing ability, delaying burn-through or wing collapse until after evacuation is complete.

Fires starting in the wings are also easier to spot when you have over 100 people looking out of the windows trying to get that perfect instagram shot. In case of a fire detection fault this gives a huge safety advantage and provides the crew with valuable extra seconds to save your life.

References ▾

Related Posts