There are 5 main types of aircraft jet engines. Each have their benefits, drawbacks, and best use cases. Learn more about the different types of turbine engines in this article.

Table of Contents

The concept of gas-powered types of aircraft engines has improved significantly since 1903. The gas turbine could produce enough power that could keep an aircraft running.

Gas-powered aircraft engines were first designed by Aegidius Elling, a renowned Norwegian inventor. With 11 horsepower, these engines were a massive feat back then.

Gas-powered aircraft engines have since come a long way, and they now come in all sizes and shape. Some engines can produce a lot more power than the 1903 engines. Here are the common types of aircraft engines, including the pros and cons of each engine.

1. Turboprop Engine

The turboprop engine is a turbojet engine that uses a gearing system to connect to the aircraft propeller. The gearbox of an aircraft comes with a turbojet that spins the shaft attached to it. The gearbox slows down the spinning shafts to allow the gear to connect to the propeller. As with Cessna 172, the propeller rotates through the air to produce thrust.

Turboprop aircraft engines are fuel-efficient and rotate at a mid-range speed, which can range between 250-400 knots. Turboprop engines are efficient at mid-range altitudes, but their gearing system can break down quickly due to their weight. Their forward airspeed is also limited.

The turboprop engine comprises a combustion chamber, which contains the pressurized air and gas, turbine, and compressor, which together runs the turbine.

The gas and air pressure create the power that drives the compressor. The propulsion efficiency of turboprop aircraft engines outweighs turbojet engine at flight speed below 500 knots. Though the diameter of the propellers of modern turboprop engines is small, these engines are equipped with many blades, which makes an aircraft stable at high altitude.

These blades are scimitar-shaped, and the edges of their tips are swept back for efficiency at high flight speeds. Aircraft engines with such propellers are referred to as propfans. Like the turbofan aircraft engine, the turboprop engine converts gas stream energy into mechanical power to derive its propulsion. It produces enough power to drive the propeller load, accessories, and compressor. These types of engines in aircraft come with a shaft attached to the turbine that drives the propeller through the reduction gear system.

The first turboprop engine was designed in Budapest in 1938. It was tested in August 1940, but it was later abandoned when the world war broke out. Max Mueller initiated the designing and launch of the world’s first turboprop aircraft engine that started to operate in 1942.

2. Turbojet Engine

The concept of the turbojet aircraft engine is simple. It entails taking air in from the engine’s rear side and then compressing it in the compressor. But fuel has to be added to the combustion chamber and burned to raise the fluid mixture temperature to about 1000 degrees.

The hot air that is produced is then pushed through a turbine that rotates the compressor. The pressure at the discharge of the turbine should be twice the pressure in the atmosphere. However, that depends on the efficiency level of an aircraft engine. The excessive pressure then moves to the nozzle that then generates gas streams, which are responsible for creating a thrust.

An afterburner can be employed to obtain a substantial increase in thrust. The afterburner can refer to a second combustion chamber that sits between the nozzle and the turbine. Its role is to heat the gas before it gets to the nozzle. Increase in temperature results in about 40% increase in thrust when an aircraft is taking off, and the push can increase at high speed once the aircraft gets in the air.

These are reaction aircraft engines, which expand gases to allow the plane to push hard forward against the atmospheric pressure. It sucks in air and then squeezes or compresses it to enable an aircraft to fly. Turbines start to spin once these gasses flow through the engine. The gasses then bounce back to the turbine and shoot out of the front of the exhaust, propelling an aircraft forward. The turbojet works by passing air through the intake, compressor, turbine, combustion chamber, and exhaust.

Parts of the Turbojet Engine

Air Intake

The tube attached to the front of a turbojet engine. While it may appear simple, it contributes a lot to the efficiency of an aircraft engine. Its role is to direct air into the blades of the compressor, and it can help minimize the loss of air into the engine at low speeds. The air intake can help slow the flow of air when the aircraft is flying at high speed. No matter how fast a plane is moving, the air flowing into the engine should be subsonic.

The Combustion Chamber

The magic starts at the combustion chamber. The chamber combines the high pressure to ignite the mixture. Combustion continues as the mixture or fuel continues to flow through the engine to the compressor and turbine. Turbojet aircraft engines run lean because the engine requires an extra flow of air to remain cool.

The Compressor

The role of the turbine in the rear of the aircraft engine is to drive the compressor. It compresses the incoming air to increase the atmospheric pressure. The compressor comprises of a series of fans, with each containing small blades. The role of the compressor is to compress the air as it passes each stage of compression.

Exhaust

The air mixture and burned fuel shoots out of the engine through an exhaust nozzle. The engine produces thrust as the compressed air pulls out of the front side of the compressor, which then pushes the aircraft forward.

Turbines

These are a series of fans, which work the same as a windmill. Their role is to absorb energy as the high-speed air flows through the compressor. Turbines have blades that are attached to the shaft so that they can rotate it. Turbojet aircraft engines have an excellent design.

3. Turboshaft Engine

The turboshaft engine is a form of gas-powered turbine that operates the same as a turboprop engine. But unlike a turboprop engine, turboshaft engines don’t drive a propeller. Instead, it is used in helicopters to provide power to the rotor.

Turboshaft engines are designed in a way that makes the speed of a helicopter rotor to rotate independently of the gas generator’s speed. That allows the speed of a helicopter rotor to remain constant even when the gas generator’s speed declines. It also modulates the power that a helicopter produces.

Turboshaft aircraft engines are commonly used on helicopters. The only difference between turbojets and turboshafts is that the latter uses much of their power for turning a turbine instead of producing thrust. The turboshaft engine is similar to a turbojet engine, but it has a large shaft that connects the front to the back. Since most of the turboshaft engines are used on helicopters, the shaft connects to the transmission of the rotor blade.

Most parts of this engine operate the same as a turbojet engine. Its turbines are equipped with a shaft to power the rotor blade transmission. The role of the rotor blade transmission is to transfer rotation from the shaft to the rotor blade. Turboshaft engines are a little smaller than piston engines and have a higher weight ratio compared to piston engines. The only downside of these engines is that their gear systems are complex and break down easily.

Turboshaft engines derive their propulsion through the conversion of high-speed gasses into mechanical power to run accessories such as the turbine and compressor. Like the turboprop engine, the shaft attached to the turboshaft engine drives both the aircraft propeller and rotor blade transmission of a helicopter. It uses the reduction gearbox to propel an aircraft forward.

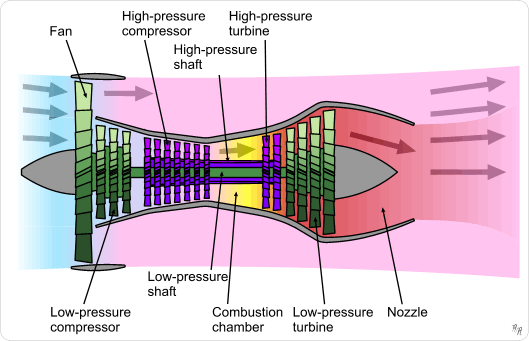

4. Turbofan Engine

Turbofan jet engines are equipped with a massive fan at the front for sucking in air. For turbofan jet engines, most of the air flow around the exterior of an aircraft engine to give the plane more thrust even at low speeds and make it quiet.

Turbofan jet engines are powering most of todays airliners. All the air that enters the intake of a turbofan jet engine flows through the generator that produces the hot air. This generator comprises of a turbine, combustion chamber, and compressor. Only a small percentage of the air that passes through the turbofan engine reaches all the way to the combustion chamber.

The rest of the air passes through a low-pressure compressor or fan, after when it is mixed with the produced gas or ejected directly. The objective of this system is to help achieve a higher thrust while maintaining the same level of consumption. The turbofan jet engine cut back the velocity within the same level of power supply and increases the flow of the total air-mass to achieve this.

The turbofan aircraft engine is an upgraded version of turboprop and turbojet engines. It works the same as a turbojet engine, but it has a ducted fan in its front. The fan cools the engine, creates additional thrust, and lowers the noise of the aircraft engine.

The inlet air of turbofan engines is separated into two streams. One stream flows through the core of the engine while the other bypass air and flows around the engine. The air that bypasses flows through the engine, where a duct fan accelerates it to produce additional thrust. The ducted fan keeps pushing the air through the engine, which then continues to increase thrust.

Turbofan aircraft engines are quieter than turbojets and fuel-efficient. Their design also looks incredible. However, these engines are inefficient at high altitudes, and their frontal area is larger than turbojets, which makes them a little heavy.

Turbofan aircraft engines are fitted with a duct at the rear of the engine. An independent turbine attached to the front of the compressor usually drives the turbine at the same speed as the compressor. The air from the fan does not mix with the engine air, but it can be ducted back to mix with the air at the front of the engine. The exhaust gas produces less than 25% of the total thrust, while 75% comes from the attached fans.

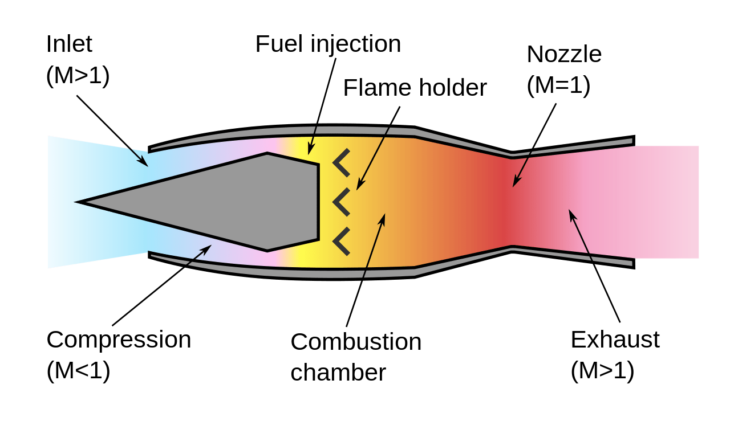

5. Ramjet Engine

These are the lightest types of engines in aircraft and come with no moving components. The speed of an aircraft is responsible for forcing air into the engine. Ramjet operates the same as a turbojet, except that the rotating parts are not present. However, the fact that the compression ratio depends on the speed of an aircraft restricts the application of ramjet engines.

Unlike other engines, the ramjet does not develop static thrust; instead, it generates little thrust below the speed of the sound. That means an aircraft running on a ramjet engine requires assistance when taking off, which could be in the form of another aircraft. The ramjet engine has been used in space vehicles and several guided-missile systems.

Related Posts